x

- Company

- Business

- Our Presence

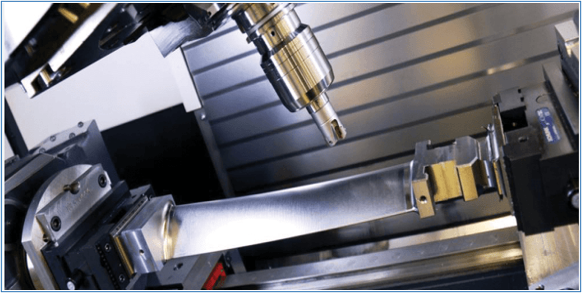

- Facilities

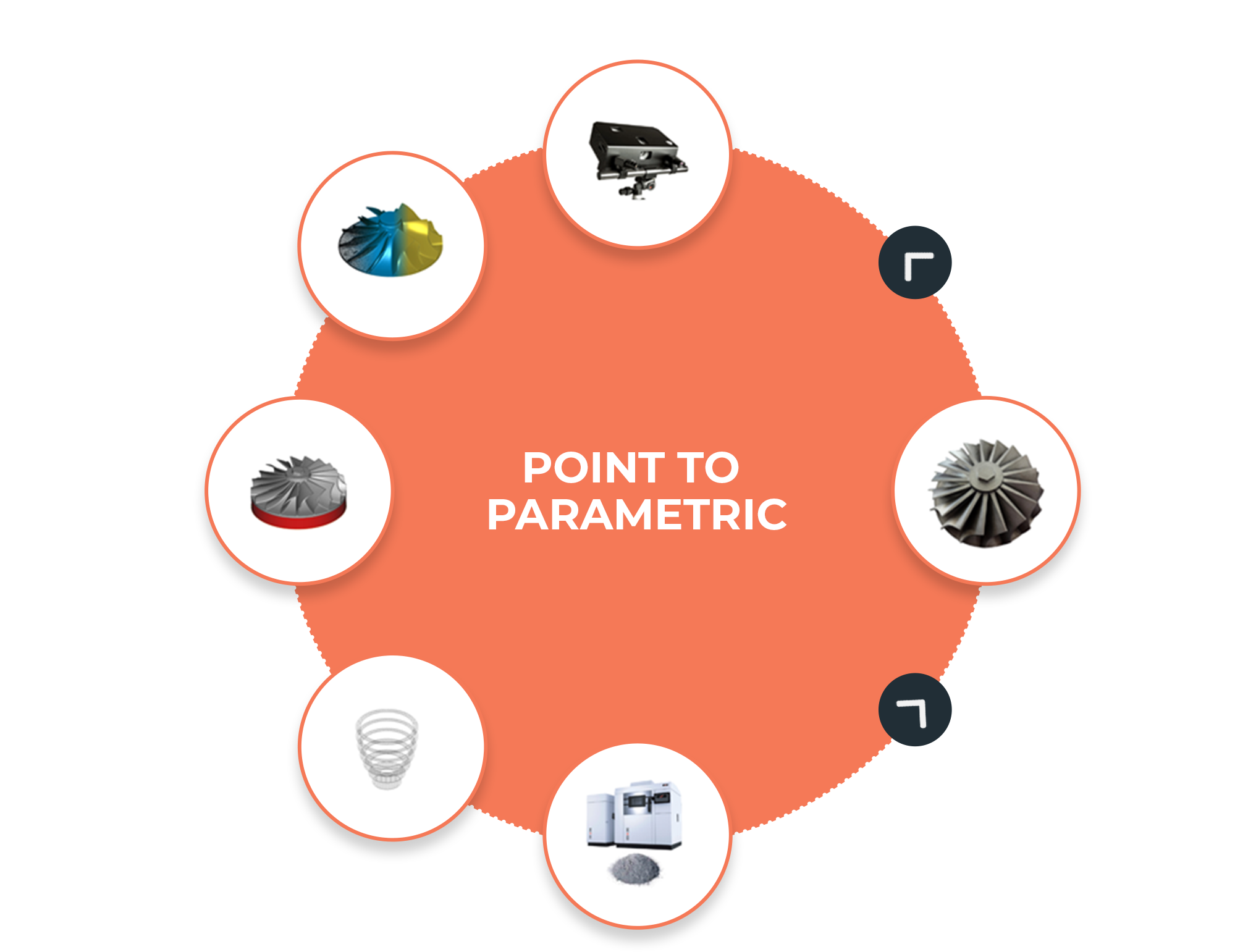

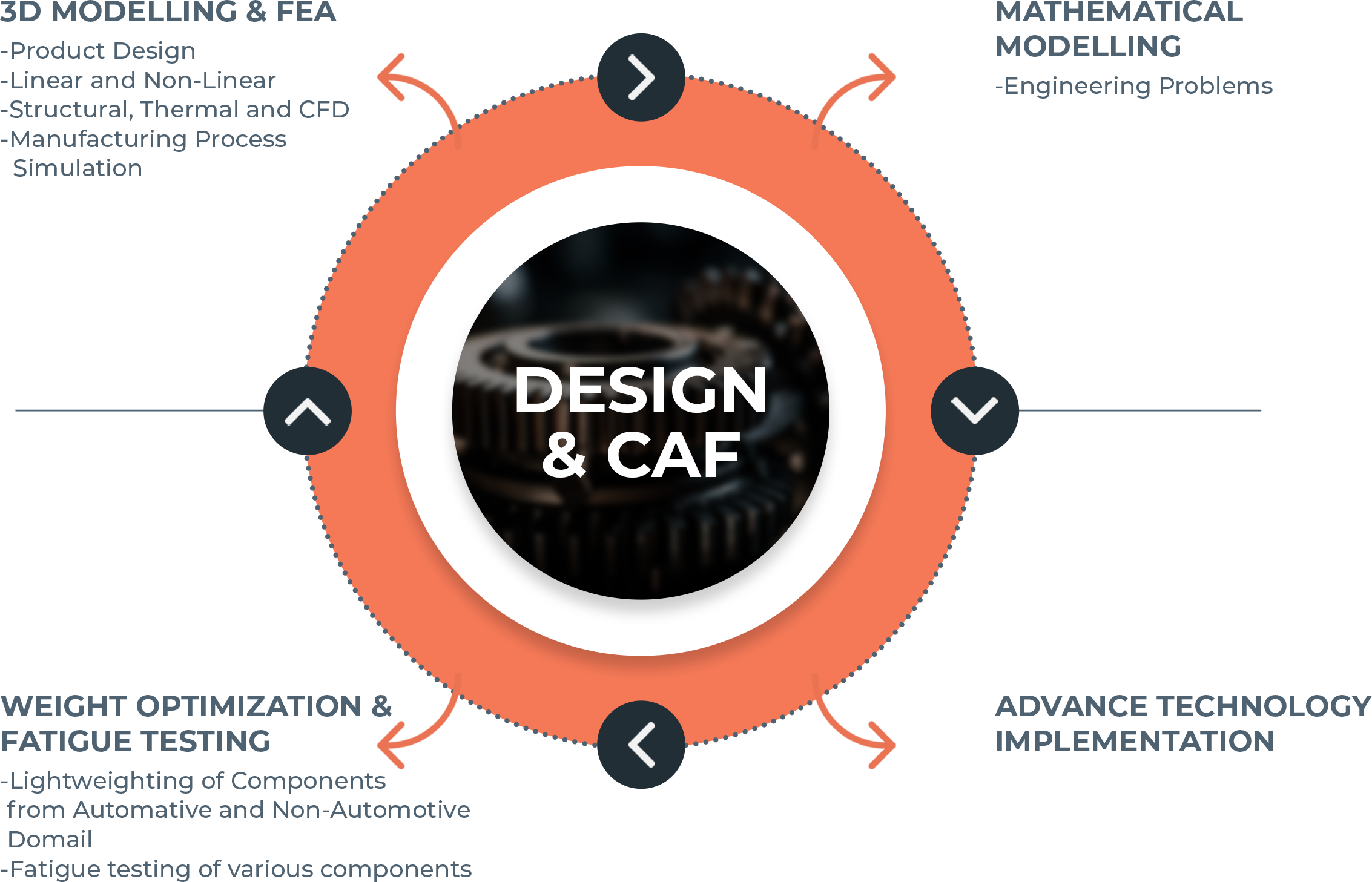

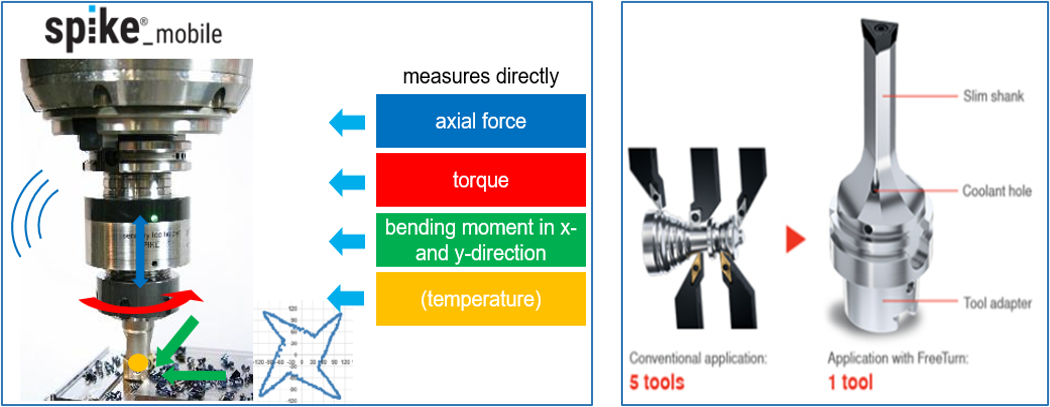

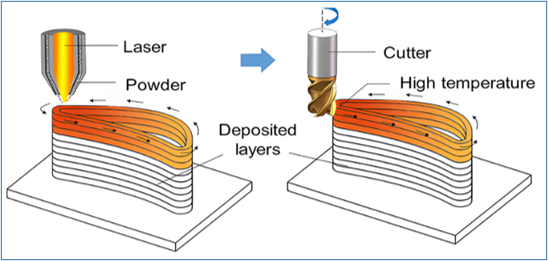

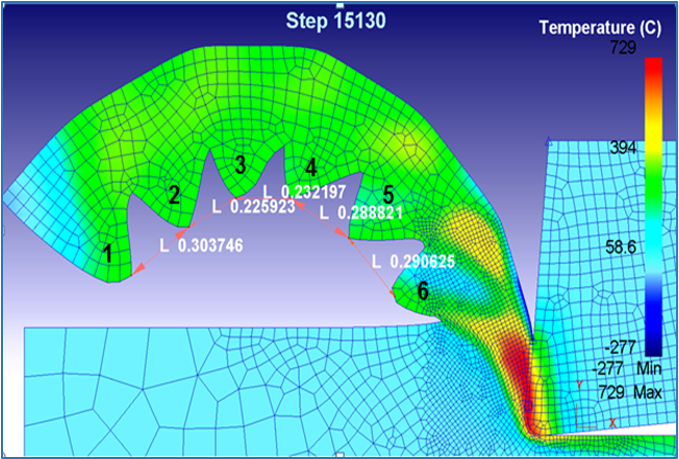

- Technology & Innovation

-

Investors

-

x

- Overview

- Shareholder’s Satisfaction Survey

- Disclosure under Regulation 46 of SEBI (LODR) Regulations

- Disclosure under Regulation 62 of SEBI (LODR) Regulations

- Shareholder's information +

- Corporate Governance +

-

Financial Information

+

- Balance Sheet

- Profit and Loss

- Ten Year Trends

- Quarterly Results

Financial- -

Stock Information

+

- Live Stock Quotes

- Share Price Movement

Stock Information- - Investors Kit +

- Contact Us

- KYC Form

- AGM

-

QIP - 2024

+

- Pre-placement Document

- Placement Document

QIP - 2024-

Investors -

CSR & Sustainability

-

x

- CSR +

- ESR & Sustainability +

- ESG Profile

CSR & Sustainability - Media

-

Careers

-

x

- Careers

-

Newsletters

+

- Apr - Sept 2024

- Screen-March 2024

- Screen-Sept 2023

Newsletters-

Careers